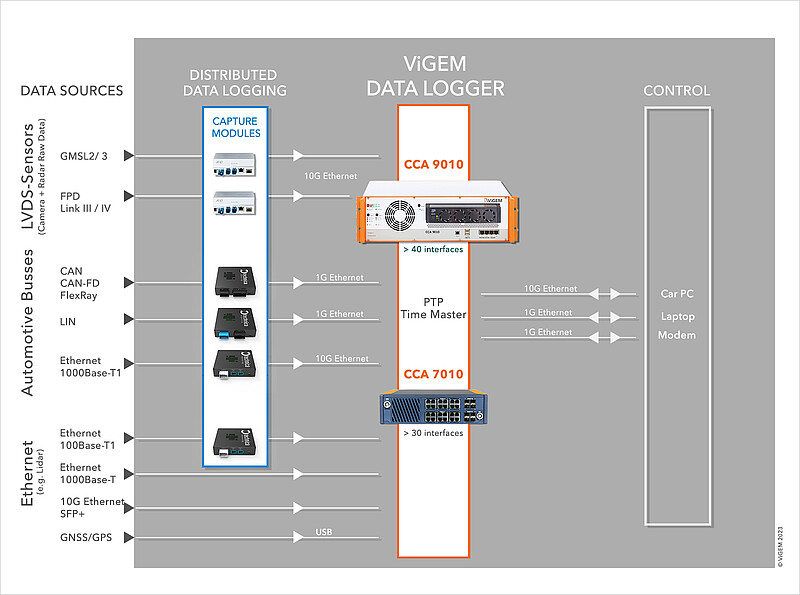

In order to record automotive interfaces such as CAN-FD, FlexRay, LIN or Ethernet (10Base-T1S, 100Base-T1 or 1000Base-T1) as well as proprietary camera interfaces such as FPD-Link III or GSML2, external Capture Modules (also called measurement adapters) are connected to the central ViGEM data logger. These Capture Modules convert the incoming data and forward it to the data logger via robust Ethernet connections.

The ViGEM data loggers offer up to 40 standard Ethernet interfaces (1000Base-T and SFP+/SFP28) with up to 25 Gbit/s:

- Time synchronization according to IEEE 802.1AS (gPTP) or IEEE 1588-2008 (1588 V2)

- Connection of Capture Modules or measurement adapters via PLP, TECMP or the new ASAM CMP standard

- Direct connection of control units, lidar or interface modules via Ethernet-RAW, UDP, TCP, XCP-over-TCP

- For recording CAN, CAN-FD, FlexRay, LIN, 10Base-T1S, 100Base-T1, 1000Base-T1 we recommend the Capture Modules of the company Technica Engineering. The connection of further Capture Modules is possible.

- For recording FPD-Link III or GSML2 we recommend the SerDes logging adapters of the company AED Vantage. The connection of further Capture Modules is possible.

- Proven compatibility: The interaction of CCA data loggers and Capture Modules is constantly tested in the ViGEM Test Center within the scope of compatibility checks. Our engineering service will assist you with your project-specific developments, adaptations and functional enhancements from project planning to the start of production.